Posted by: Cheryl Savit, Savvy Words for KitchenVisions & Kevin Cradock Builders

The supply chain disruptions caused by the pandemic aren’t news to anyone in the building industry – everyone has lived with the price fluctuations, a dearth of materials, and the long wait for appliances all year.

“We’re still having major supply chain issues and I don’t see it getting better anytime soon. At this point, we are moving toward ordering appliances and windows before we start projects” Kevin Cradock Owner of Kevin Cradock Builders

However, some good news appears to be on the horizon – lumber prices have dropped for three consecutive months after reaching an all-time high. While clients may not be realizing the savings immediately, it is good news for remodelers and builders, as margins have been super tight for months.

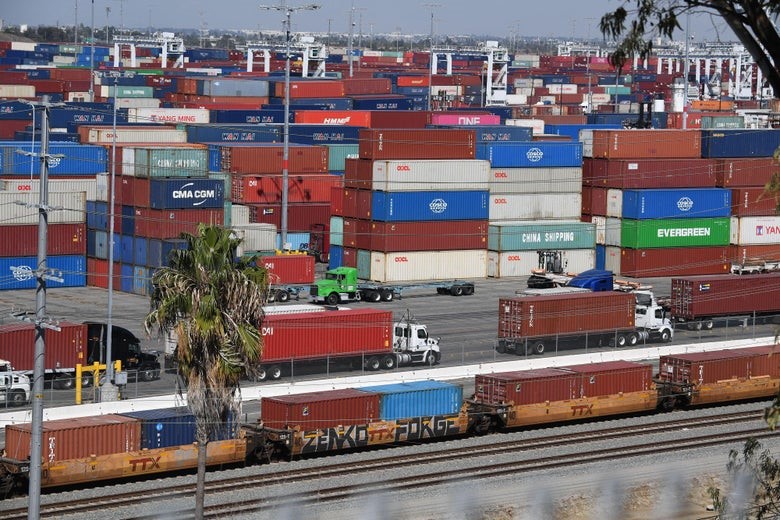

Robyn Beck/Getty Images

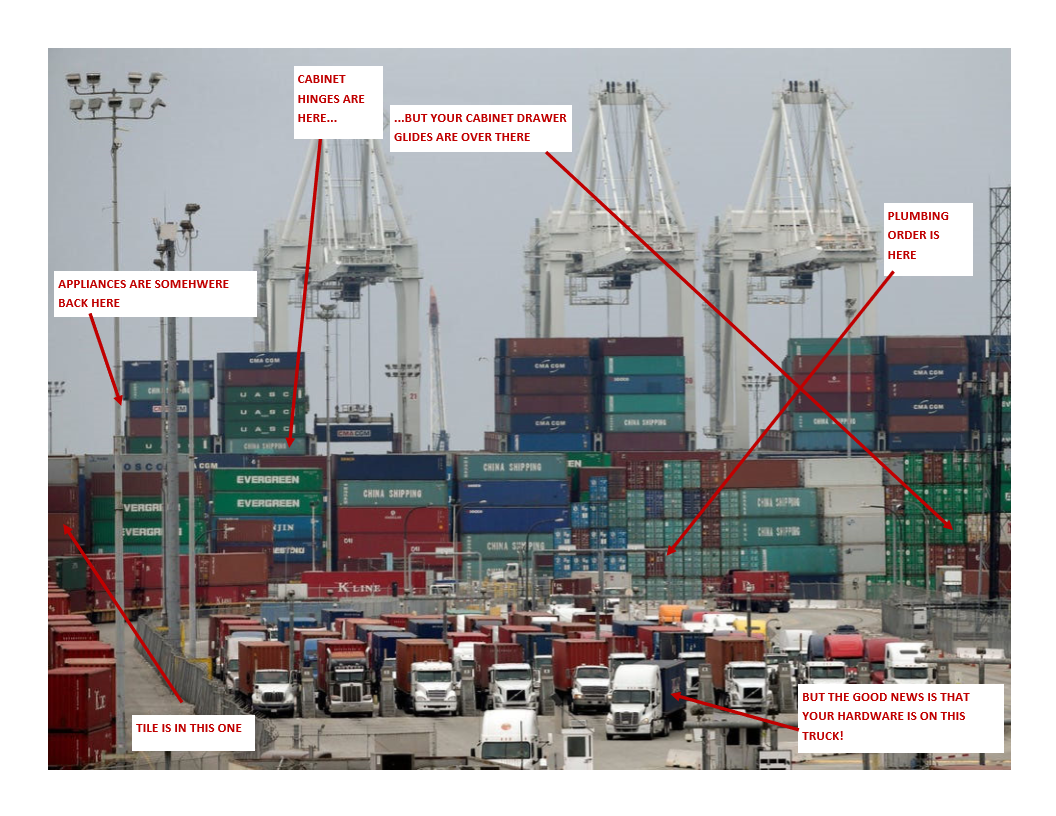

Before we all begin celebrating, here’s the bad news: the supply chain is still a wreck. First of all, there is the back-up at ports, especially Los Angeles, where container ships are stacked like Legos. As demand for household goods – and the rise in remodeling and building projects rose – the pressure on manufacturing reached its boiling point because many factories were shut down because of the pandemic and slow to ramp up production. One case in point is the foam industry with its domino effect: without the key chemical ingredients to make the foam, the industry has been at a standstill causing major headaches for furniture and appliance manufacturers who need the foam for their products.

Perhaps one of the biggest woes for remodelers these days is the long wait for appliances. Steve Sheinkopf, the head of Boston retailer Yale Appliance, told the Wall Street Journal that “he has lent out so many cheaper appliances to customers that he feels like he’s running a lending library. His staff has been berated by homeowners missing ovens and dishwashers. He said that he added ‘combat pay’ and threw ice-cream parties and free pizza to try to boost morale.”

“Cabinets that used to take 6-8 weeks are now anywhere from 14 to 16 weeks. And some of our cabinet lines are up to 28 weeks. It’s absurd,” said Jodi Swartz, Owner and Principal Designer of KitchenVisions. “Not everything is coming in correctly. The quality doesn’t seem the same. Items are not packed well or painted well. The factories are overworked. They are having trouble finding workers. Our clients are as frustrated as we are. We’re trying to keep people in a state of least dissatisfaction.”

However, before placing the blame solely on the pandemic, let’s be honest: there were issues with the supply chain before Covid struck that have only been exacerbated by these circumstances. If you believe in silver linings and a brighter future, there may be one coming: analyzing where systems have broken down and repairing those systems to provide better supply chain flow and services in 2022 and beyond.

LINKS:

- https://fortune.com/2021/08/28/lumber-prices-2021-chart-update-price-of-lumber-going-down-sharply/

- https://slate.com/business/2021/10/supply-chain-shortages-retail-united-states-explained.html

- https://www.wsj.com/articles/oven-fridge-home-appliance-delays-kitchen-renovation-11633557751

- https://abcnews.go.com/Politics/whats-causing-americas-massive-supply-chain-disruptions/story?id=80587129